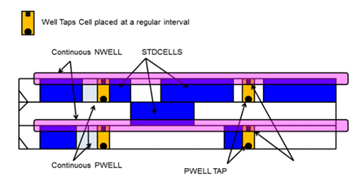

Well

taps (Tap Cells): They are traditionally used so that Vdd

or GND are connected to substrate or n-well respectively. This is to help tie

Vdd and GND which results in lesser drift and prevention from latchup.

End

cap Cells: The library cells do not have cell connectivity as

they are only connected to power and ground rails, thus to ensure that gaps do

not occur between well and implant layer and to prevent the DRC violations by

satisfying well tie-off requirements for core rows we use end-cap cells.

Decap Cells:

They are temporary capacitors which are added in the design between power and

ground rails to counter the functional failure due to dynamic IR drop. Dynamic

IR Drop happens at the active edge of the clock at which a high current is

drawn from the power grid for a small duration. If power source is far from a

flop the chances are there that flop can go into metastable state. To overcome

decaps are added, when current requirement is high this decaps discharge and

provide boost to the power grid.

decap cell.

Tie Cells:

Tie-high and Tie-Low cells are used to connect the gate of the transistor to

either power or ground. In Lower technology nodes, if the gate is connected to

power/ground the transistor might be turned on/off due to power or ground

bounce. These cells are part of standard-cell library. The cells which require

Vdd (Typically constant signals tied to 1) connect to Tie high cells The cells

which require Vss/Gnd (Typically constant signals tied to 0) connect to Tie Low

cells.

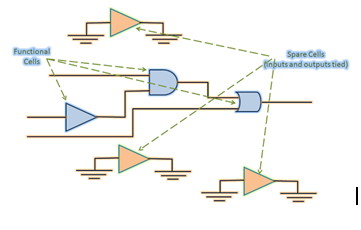

Spare

cells: These are just that. They are extra cells placed

in your layout in anticipation of a future ECO. When I say future, I mean after

you taped out and got your silicon back. After silicon tests complete, it might

become necessary to have some changes to the design. There might be a bug, or a

very easy feature that will make the chip more valuable. This is where you try

to use the existing “spare” cells in your design to incorporate the design change.

For example, if you need a logic change that requires addition of an AND cell,

you can use an existing spare AND to make this change. This way, you are

ensuring that the base layer masks need no regeneration. The metal connections

have changed, and hence only metal masks are regenerated for the next

fabrication.

Kinds

of spare cells: There are many variants of spare cells

in the design. Designs are full of spare inverters, buffers, nand, nor and

specially designed configurable spare cells.

Inserting

Spare Cells

Spare cells need to

added while the initial implementation. There are two ways to do this.

The designer adds separate modules with

the required cells. You start your PnR with spare cells included, and must make

sure that the tool hasn't optimized them away. There can be more than one such

spare modules, and they will be typically named spare* or some such

combination. The inputs are tied to power or ground nets, as floating gates shouldn't be allowed in the layout. The outputs are left unconnected.

Spare

cells can also be added to design by including cells in Netlist itself.

No comments:

Post a Comment